Canadian chicken is raised by local farmers who follow mandatory guidelines that prioritize animal well-being and food safety.

Planning and Responsible Breeding

The process starts with careful planning—farmers assess market needs and set production cycles every eight weeks to help match supply with demand and reduce waste. This collaborative approach, called supply management, ensures that chicken is readily available and responsibly managed for Canadian families.

Breeding, Hatching, and Early Care

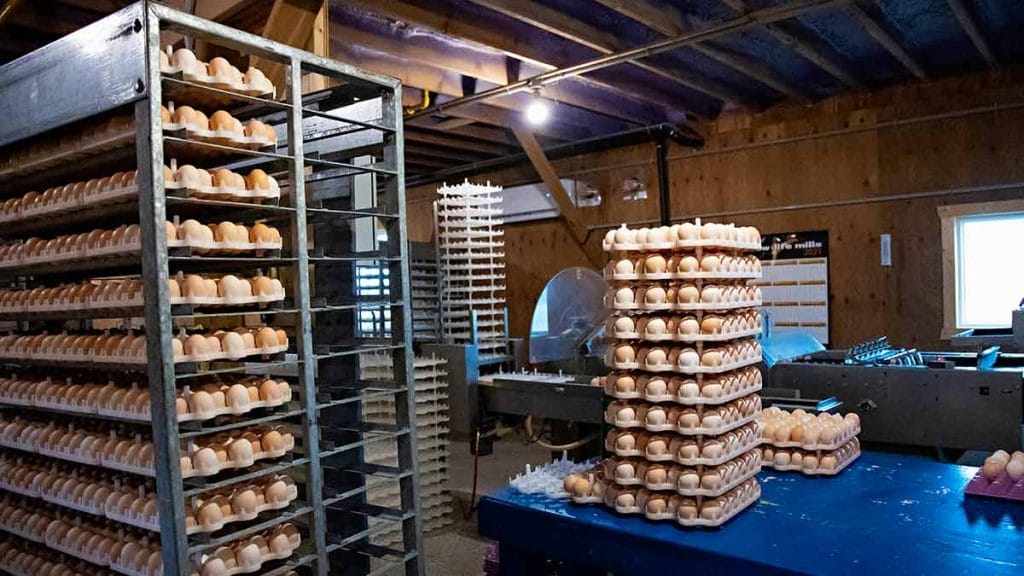

‘Broiler breeders’ are chicken farmers who raise female and male birds called hens and roosters to produce fertilized eggs. The fertilized eggs are then sent to hatcheries and incubated for about 21 days. Once hatched, the chicks are transported to local farms where the barns are ready with fresh bedding and warm temperatures for the new chicks.

Farm Fact: Broiler chickens are raised specifically for meat production. The eggs you buy at the grocery store are unfertilized and are produced by laying hens raised specifically to lay eggs for human consumption. Those chickens are called ‘layers’.

Life on Canadian Farms

Broiler chickens are raised “free run,” meaning they move freely within barns and can express natural behaviours like dustbathing and socializing. Broiler chickens in Canada are not kept in cages.

Chickens have access to fresh food and water stations. Canadian regulations strictly prohibit hormones and steroids in chicken production.

All 2,800 Canadian chicken farmers follow biosecurity protocols that minimize the risk of bringing in unwanted pathogens and are certified on the Raised by a Canadian Farmer On-Farm Safety. These protocols include disinfecting the barn, changing into dedicated boots clothing when entering the barns and controlling who has access – all to minimize chickens’ exposure to bacteria and pathogens.

Care, Growth, and Monitoring

All 2,800 Canadian chicken farms are also certified on the Raised by a Canadian Farmer Animal Care Program, which emphasizes proper animal care throughout each step of the production cycle. Farmers actively monitor chicken health and comfort using modern tools and hands-on care. They can keep tabs on the temperature of the barn, feed and water levels and any alerts through the use of their smart phone. As well, farmers walk the barns at least twice a day to check on bird health and make sure all equipment is running as it should. Most broiler chickens reach a market weight of around 2 kg in about 35–40 days, with every step taken to ensure their wellbeing and growth.

Humane Processing and Delivery

When chickens are ready for market, they are carefully moved to processing plants using trucks designed for their comfort. Chickens are processed into the different cuts of meat that you can buy at the store. Farmers and processors work together to ensure humane treatment and maintain strict safety standards at every stage—from the farm to the table.

Confident Choices for Canadians

Canadian chicken is produced with transparency and accountability from start to finish.

Animal care and food safety are continually prioritized through industry best practices and government regulations.

Canadian chicken is produced under national, mandatory standards for animal care and food safety. It’s an excellent source of protein and essential nutrients, raised by Canada’s dedicated local farmers.

Bannock’s Path From Survival To Celebration

Bannock’s Path From Survival To Celebration